EMC

Accura

Airtec

Aignep

Mecair

Mütec

Bürkert

FineTek

Pneumax

ROSS Controls

Master Pneumatic

SmartMeasurement

Control Concepts

Products

Process & Control Valves

Process & Control Valves

Control Concepts Documentation

ACOUSTICLEAN QUICK QUOTE SHEET

ACOUSTICLEAN APPLICATION DATASHEET

AcoustiClean Sonic Horn Installation and Operation Instructions Manual

ACOUSTICLEAN Model 17220 Product Information Sheet

AcoustiClean Model 17220 Model ACL 17220 Dimensional Diagram Drawings

ACOUSTICLEAN Model 34230 Product Information Sheet

AcoustiClean Model 17220 Model ACL 34230 Dimensional Diagram Drawings

ACOUSTICLEAN Model 9475 Product Information Sheet

AcoustiClean Model 17220 Model ACL 9475 Dimensional Diagram Drawings

ACOUSTICLEAN Model A600 Product Information Sheet

AcoustiClean Model 17220 Model A600 Dimensional Diagram Drawings

CLEAN LIGHT MATERIAL BUILDUP FROM LARGE SURFACES AREAS

AcoustiClean® Sonic Horns produce high-energy, low-frequency sound vibrations that disperse dry material. Compressed air is applied to a sound generator, which vibrates a titanium diaphragm. The sound waves clear the material, to clean your material handling equipment.

EASY TO INSTALL

Reduce plant shutdowns and improve material flow

SUITABLE FOR HIGH HEAT AND FOOD APPLICATION

Made of cast iron or stainless steel

LOW MAINTENANCE

Titanium diaphragm is the only moving part

| EFFICIENCY | QUALITY | SAFETY | SAVINGS |

| Reduce plant shutdowns and improve material handling flow | Prevent cross-contamination during production | Replace dangerous and expensive manual cleaning | Increase the energy/heat transfer efficiency and lifespan of machines |

ACOUSTICLEAN SONIC HORN

The size and shape of the sonic horn’s bell section determines the acoustic energy produced.

Longer, larger horns produce more energy to clean larger areas.

ACL 17220 |

ACL 34230 |

ACL 9475 |

A600 |

|

|

|

|

|

|

| Our smallest sonic horn, ideal for fluidizing material inside hoppers, bins and boilers | A two-section sonic horn ideal for use on bins and silos to break ratholing and plugging. | Common applications include baghouses, SCRs and ESP. | Ideal for fluidizing material inside hoppers, bins and boilers. | |

CLEANING DISTANCE |

15 feet (4.57m) | 30 feet (9.14m) | 60 feet (18.29m) | 15 feet (4.57m) |

CLEANING DIAMETER |

6 feet (1.83m) | 15 feet (4.57m) | 20 feet (6.10m) | 6 feet (1.83m) |

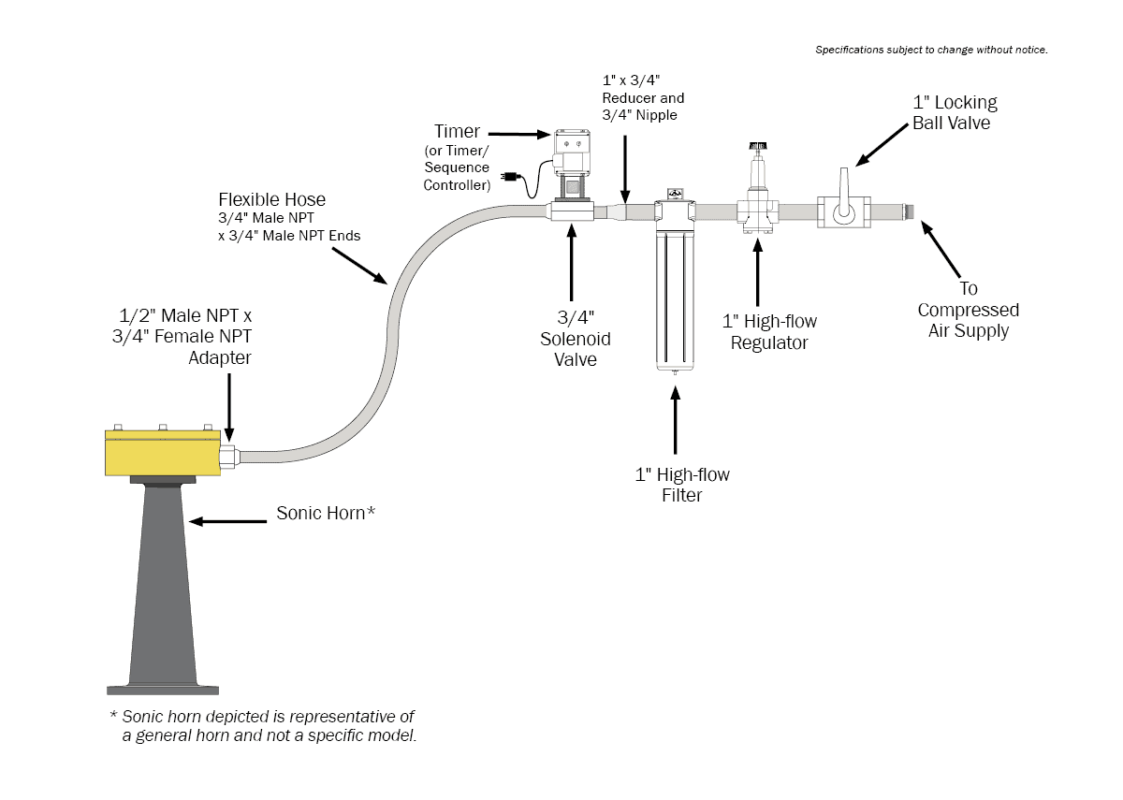

ACOUSTICLEAN SONIC HORN ACCESSORIES

For easy installation and maintenance, we provide everything you need for your sonic material activation system.

Solenoid Valve to control air flow

Stainless Steel Flex Hose to connect the valve and piping to compressor

Timers to control the interval and duration of sound waves. A control box can control multiple devices

Control Box Basic equipment for many devices

Sound Generators replaced or re-machined after 5 years of typical service

Titanium Diaphragm the only moving part, which must be replaced yearly

FIND YOUR FLOW

Complex processes or material flow issues may need special installation or combination of equipment.

TYPE OF MATERIAL |

SIZE OF VESSEL |

TYPE OF VESSEL |

|

AcoustiClean Sonic Horns work well on dry, powdery material. If material moisture is elevated or significant, the best alternative is the AirSweep System. |

For very large vessels, consider installing AirSweep at the bottom and AcoustiClean sonic horns at the top. | For boilers, the most effective installation will have the horn(s) blowing in the same direction as the pipes. |

ACOUSTICLEAN SONIC HORN APPLICATIONS

Boilers

Cleans heat transfer surfaces for better heat transfer efficiency.

Baghouses

Helps reduce pressure drop across surfaces.

Industrial Fans

Eliminates material build-up on blades.

Electrostatic Precipitators

Eliminates rapping system and wear to plates and wires.

Silos, Bins, and Hoppers

Eliminates ratholing, bridging, and prevents particulate build-up.

Selective Catalytic Reduction , SCR

Disperses particulates that, over time, can impede the performance of selective catalytic converters.

THE WORLD’S LARGEST BRANDS TRUST ACOUSTICLEAN® SYSTEMS

02-384-6060 info@factocomponents.co.th www.factocomponents.co.th